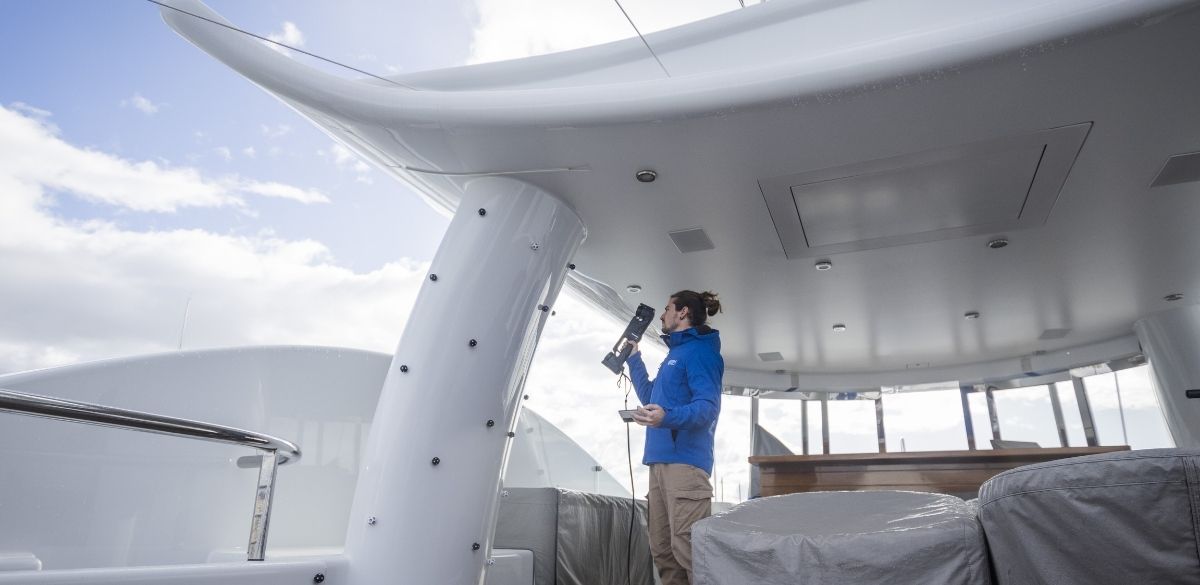

Following a significant investment in technology, equipment, and an increase in personnel, BMComposites is pleased to announce the introduction of on-site 3D scanning and enhanced design services.

The company’s newly acquired 3D scanning tools enable the capture of data over large, complex areas with a high level of accuracy. BMComposites looks forward to applying this technology to a broader range of projects, including the design of new parts for superyacht refits and support in yacht surveys.

“This investment allows us to work with much greater speed and accuracy; it has revolutionised the way we operate,” said Mark Branagh, Managing Director. “We can now redesign, reverse engineer, fit, or build just about anything with total precision and without revisiting the vessel, giving us confidence in first-time fitting—whatever the task. For larger refits, the real benefit lies in our ability to collaborate and share accurate information with multiple international parties. We can exchange files in various formats, from dimensionally accurate photographs to full 3D models, across any platform. In an industry where deadlines and expectations are high, this is a total gamechanger in terms of efficiency.”

BMComposites’ continued investment in design and engineering has increased year on year and consistently proven its value through improved efficiency, professionalism, and clearer communication of design intent to partners and clients. The company now offers a complete design package that extends beyond composites. Its five-strong design team also delivers high-quality 3D rendering, structural engineering, geometry verification, and finite element analysis.

To learn more about BMComposites’ structural design services for new builds and refit projects go to www.bmcomposites.com

0 Comments