Committed to providing the perfect blend of sailmaking art, science and customer service, and located just 10 minutes from the Port of Palma at the epicentre of the superyacht community, Doyle Palma, founded in May 2000, has what is undoubtedly one of the most advanced in-house sail production systems on the planet.

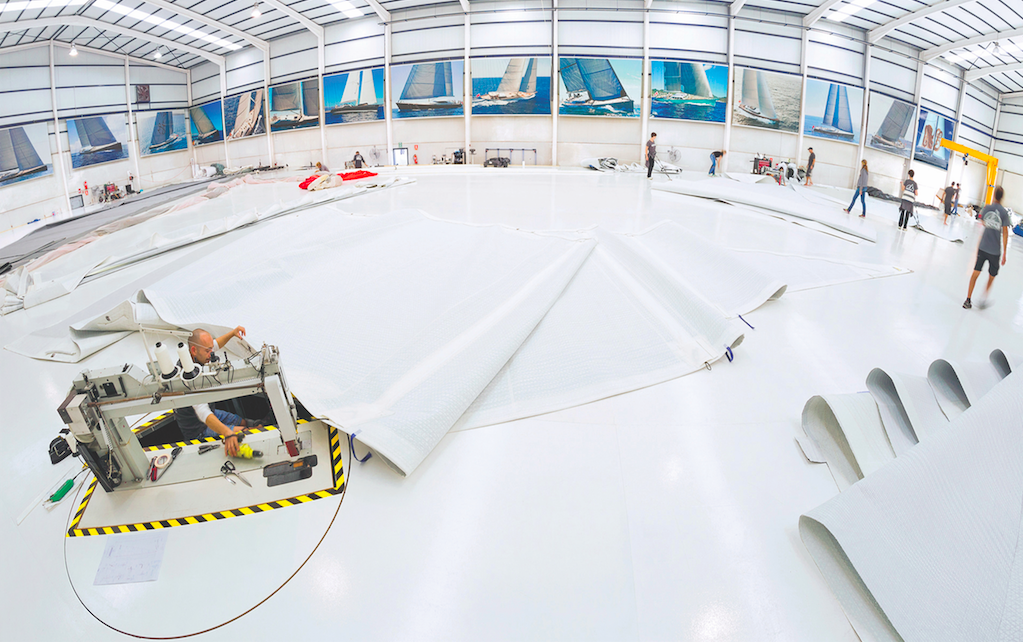

One of the few companies in Spain that deals with every aspect of the sailmaking process, their two custom-designed lofts total a vast 2,355sqm: an 800sqm loft for downwind sail production and maintenance, and their piece de resistance – the 1,555sqm state-of-the-art full-service loft, dedicated to the art of creating the very finest in bespoke superyacht sails.

During a large expansion in 2011, this new facility was purposely-designed by owners Fiona Bruce, Russell Thom and Quinny Houry to facilitate the increasing demand for, and size of superyacht sails seen over their 16 years in the business – an ambitious loft development that has to be one of the real wonders of the sailing world. Small enough that their sailmakers can give each customer the time and personal attention they require, it’s also superbly-equipped with everything they need to build, manoeuvre and service today’s ever-expanding sails: from its 1000-kilo crane, to the 800-kilo A-frame, which help effortlessly manipulate the sails around the loft.

There’s also the ingenious raised finishing floor, meaning the sailmaker can sit flush with the floor in specially-designed swivel bays. This allows them to move the machine – rather than the vast amount of heavy sail material – around with ease, (essential when dealing with up to 1.5 tonnes of sail), while two heavy-duty XL sewing machines are able to sew through 4cm of carbon fibre.

Doyle’s dynamic on-site team, renowned for their hands-on attitude, are with their customers every step of the way, using their impeccable attention-to-engineering-detail, construction quality, and application of the latest technologies to determine their clients’ sailing goals and experience, and to identify the elements of the rig or deck hardware that will affect the way they will set, trim, and furl. The design process also includes fully-interactive 3D graphic modelling so customers can accurately visualise the phenomenon of aerodynamic flow as it passes through the sail plan.

The result? The most appropriate shape design, cloth selection and component hardware for each individual client’s needs; a sail that is more dependable, affordable, easily-maintained and longer-lasting; and one that performs better than any comparable product out there. Little wonder they are the sailmaker of choice to some of the world’s most spectacular yachts – including the 58.4m Alloy Kokomo, the 52m Alloy Red Dragon, the 53m Royal Huisman Elfje, and the 50m Fitzroy Ohana, to name just a few.

Add to this Doyle’s brilliant aftercare service, including their covered sail washing facility and a dedicated service area, and it’s easy to see why Doyle has a hugely loyal, and ever-increasing following.

Doyle Palma

+34 971 478 078

office@doylepalma.com

www.doylepalma.com

0 Comments